Aside from knowing about the tequila production process, a very frequently asked question I get as a tequila industry worker is: How is a tequila bottle made? In this blog post, I will try to answer this question. I will talk about its components and characteristics and the importance that must be taken into account to produce a good-quality bottle so you can, in the end, buy a properly bottled Casa Sauza tequila, either at the supermarket or at the different distribution or consumption centers there are.

Of which materials is a tequila bottle made of?

We have more than 182 products at Casa Sauza, the most important brands: Sauza, Hornitos, Tres Generaciones, Hacienda, 100 años, and XA. Each of these products entails a series of specific requirements for their proper distribution to the national and international markets to which they are directed.

Package information

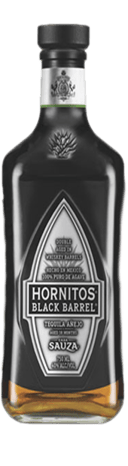

We will take as an example a product of our brand, the Hornitos "Black Barrel." It is one of the best-selling tequilas of Casa Sauza because of its taste since it goes through a double aging process in Scottish-style oak barrels. The packaging consists of:

- Bottle: A crystalline bottle is used; it undergoes a special decoration process.

- Top: Cork, raised.

- Tags: Self-adhesive front, back, and neck, elaborated with metallic inks.

- Marbete: fiscal tag for the Mexican market

- Guarantee seal: Crystalline.

- Box: Corrugated cardboard box with separators with a capacity for 12 bottles.

Packaging characteristics of a tequila bottle

Before bottling the tequila, all required materials for each product must be available on time. So, we first make sure that all of the components are prepared according to the specific requirements of the packaging line using monitoring systems and strategic planning.

The materials go through a system of automated lines that follow a consecutive flow of tequila filling, then labeling, and finally arrive at a packaging process.

What is the importance of the materials used in a tequila bottle?

The materials must comply with the specifications indicated by each brand for Marketing purposes, such as design, size, color, and graphics. In addition to the legal requirements, such as specific labeling rules for tequila, such as the label at the front and back of the product norm, They must also comply with other specifications, such as the placement of fiscal markets for the national Mexican market as well as for their export -to the countries that require it.

It is important to consider that final adaptations will be made to the packaging depending on each product, the destination country, and the means of transportation used.

The specific requirements of tequila's elaboration, packaging, and commercialization processes are stated in the Official Mexican Standard of Tequila NOM-006-SCFI-2012, Alcoholic Beverages-Tequila-Specifications.

For all the above, it is important to consider and guarantee compatibility among the individual materials for the final integration of all the parts. This brings us to a perfect combination of each detail to finally achieve a finished product with zero defects.

Learn more about tequila production processes here:

- Agave Sugar Optimization for Tequila Production

- How to make quick format changes in a packaging production line

- Lean Manufacturing in Tequila

Visit Casa Sauza to learn how our production processes' modernization delivers the purest tequila you will find in the market.

.png?width=50&height=50&name=10.CS-Redondo%20(1).png)