Throughout my 10 years experience in the tequila production process, some of the most frequent asked questions are: which are the principal sugar losses in this beverage production? In this article we will show you the different ways in which this raw material gets lost and how to improve the process efficiency.

Tequila Making Processes in which the Raw material can get lost

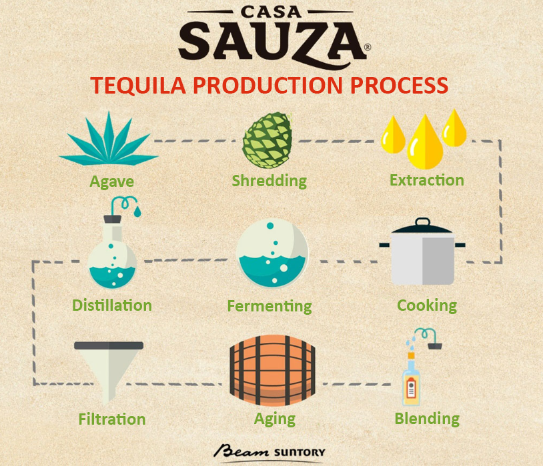

In the Tequila Industry, there are different ways to produce tequila, going from the artisanal/traditional methods to the most modern techniques but in a general description, the stages are: harvest, jima, shredding, extraction, hydrolysis, cooking, formulation, fermentation, distillation, filtration and aging. In each one of these steps and according to the used method, the raw material can get lost due to many factors.

Sugar Loss in the Agave Jima Stage

(Waiting time after the jima).

(Waiting time after the jima).

The process of jimar, consists in cutting the agave plants including the roots, and leaving just the heart of the plant, known as piña. All of this is done by workers named jimadores and for doing so, they need special cutting tools. The principal one they need is the coa, which is a semicircular object with a sharp metal blade and a wood stick to grab it.

Once the agave has been "jimado", is important to move it and process it as soon as possible, because some bacteria and fungi may consume and damage the sugar contained in the agave piña.

Sugar Loss in the Agave Shredding Stage

(Fiber size)

The goal of this process is to fraction and cut the agave in small fibers to be able to extract the sugar in the following stage. It is important to say that the smaller the fibers, the better efficiency we will have in the extraction process, and in consequence to this, we will reduce the sugar losss in the bagasse.

Sugar Loss in the Gentle Extraction with Diffuser Stage

(Hot water flow, speed)

Once the agave has been shredded in small fibers, the extraction process is next. This consists in adding hot water to the raw material through an equipment named diffiser, and achieving this way a gentle extraction.

It is very important to have an adequate hot water flow and speed when using the diffuser, because these two factors are determined by the amount of sugar contained in the agave piñas, that is to say that a batch of agave with a higher sugar concentration would need more watter and a lower speed to extract the agave sugar. At the end of this process we obtain the agave's raw juice and the bagasse as a waste.

Sugar Loss in the Hydrolysis Stage

(Temperature, time)

(Temperature, time)

The hydrolysis process consists in cooking the raw agave juice in temperatures of 120-125° C for 2 hours to transform the inuline molecule into monosaccharides (fructose and glucouse), wanting these substances to be easier to ferment by the yeasts in the next stage of the process. In this step is of vital importance to give the raw juice the proper time and temperature to avoid obtaining raw or overcooked juices at the end.

Sugar Loss in the Formulation Stage

(Ph, % sugar, temperature, cleanliess)

In this process, the recipe follows its course with the cooked agave's juice, and we prepare the ideal contidions of pH(4-6), % sugar (8-12%) and temperature (32-35 °C) for the yeasts to find an optime environment to survive and ferment the product.

It is also important to maintain all the tanks with good hygiene in every possible way to avoid bacteria in the process because it may fermentate the sugar, turning the liquid into a non-wanted product. Is in this stage were the next categories are defined: Tequila 100% y tequila.

Sugar Loss in the Fermentation Stage

(Temperature Control)

The fermentation is an anaerobic process which is performed by yeasts that consume the monosaccharids (frustouse and glucouse) and transform them in alcohol and CO2 (carbone dioxyde) with a general heat effect in the chemical reaction.

It is important to have a proper cooling system to maintain the optime temperature (32-35) and avoid reaching hih temperatures that may kill the yeasts before finishing their fermentation mission. In Casa Sauza, our fermentation process go by fast and clean because we have closed tanks and the lastest cooling and cleaning systems to assure the security and high quality of our products.

Sugar Loss in the Distillation Stage

(Distillation speed, temperature)

The distillation is basically a physical separation process . Tequila needs two distillations to obtain it's particular characteristics:

- 1.- The first distillation is called suppresing; in this stage the fermented juice passes through special distillation columns to eliminate the water residues and concentrate the alcohol.

- 2.-The second distillation needed is called reactification and it's performed using distillation stills where the final tequila product is obtained, with a temperature between 55-65°c.

It is imperative that the distillation equipment are adequate for the alcoholic/fermented juices that are depossited inside them. The temperature and the environment conditions need to meet special requirements to avoid wasting alcohol in the vinasse waste or through air venting.

All the tequila is filtered in order to remove excessive compounds and particles that may interfere with our quality standards and final tequila notes.

Sugar Loss in the Aging Stage

(Humidity in the aging storages and resting)

To be able to age tequila, it is placed in oak barrels for at least 2 months. The aged tequilas stays resting there for 1 year in 200 L white oak barrels and the extra-aged tequilas are rested for 36 months in white oak barrels.

Maintaining the proper humidity and air conditions in the resting storages is of vital importance, with the main goal of reducing damages caused by unwanted evaporations.

Through our optimization processes in Casa Sauza, we are looking after taking advantage of our raw materials and methods in the best way we can to offer to our clients a high- quality tequila.

Keep reading if you want to learn more about the Tequila Making Process and extraction methods.

Come and visit Casa Sauza so you can learn how the modernization of our production processes deliver the purest tequila that you will find in the market.

.png?width=50&height=50&name=10.CS-Redondo%20(1).png)