The maintenance planning is an important activity which allows the supervisors in the production area to achieve the planned activities in time and correctly.

Planned Maintenance

To plan the maintenance in a company, it is required to perform some activities that are listed below, and we will talk about two of them in more detail:

- That allows the person in charge to perform a maintenance intervention to identify the active.

- Which type of active will receive the intervention (machinery, building, IT equipment, etc).

- Which activity is being performed to the active

- Which materials will be required for each planned task

- What amount of time will be required for every planned task

- What number of persons will be required according to the specificity of each task

- What is the required time for the intervention

1. Identify the active

A proper method of identifying the actives must be stablished, so we could know the technical location and the equipment codification as quickly as possible. It is imperative to access to this information efficiently and know where is the equipment installed in the different areas of the process.

To establish a technical location for the different areas of the process, the "master" area must be identified. For example: dividing the plant areas in processes. This means that all the technical locations will be listed with the following nomenclature:

- 1rst level. Level XX- General Plant Name

- 2nd level. Level XX-01- Process I

- XX-02- Process II

- XX-03-Process III

Establishing the technical locations in the General Plant, the next step is to establish the sections in the area and after that, they are listed with a consecutive order of number or letters, according to its definition. By terms of choosing the best way to control the actives increasing a 3rd level in the nomenclature, for example:

In the Process I section, there are different sub-areas:

- Sub-area I

- Sub-area II

- Sub-area III

- Sub-area IV

- Sub-area V

So then, we can add these areas to the technical location structure, ending up with the following list:

- 1rt Level XX Name of the General Plant

- 2nd Level XX-01- Process I

- 3rd Level XX-01-01- sub-area I

- XX-01-02- sub-area II

- XX-01-03- sub-area III

- XX-01-04- sub-area IV

- XX-01-05- sub-area V

Keeping track of this same example, we define the next technical locations of the following process among its sub-areas:

- XX-02- Process II

- XX-03-Process III

2. What kind of active is the one receiving the intervention?

To identify the active that will receive the maintenance, we must establish the method to classify them defining a code system: We should create a code to identify the equipment, we can achieve this by a maximum of 5 characters composed by letters and numbers.

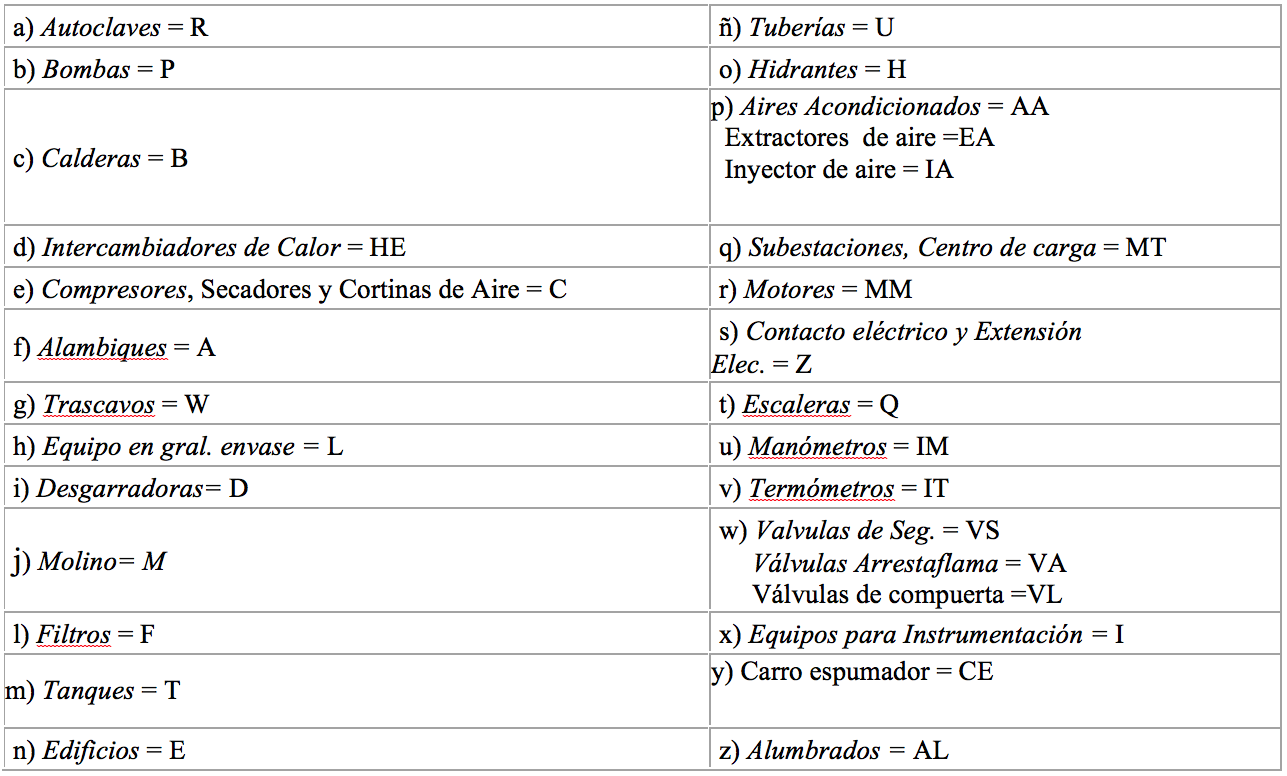

The first character should start with a letter and indicate the sub-area code (look at the a-f specification in the illustration at the bottom); the second and third letter, which in some cases correspond to the type of equipment that has been previously classified and at the end we must add a consecutive number with 2 digits according to the number of actives installed; this mechanism should be independent for each sub-area.

Clasification sub áreas:

The plant has been divided in the following sub-areas to facilitate its codification:

- a) E= Sub-area

- b) C= Sub-area

- c) F = Sub-area

- d) D = Sub-area

- e) G = Sub-area

- f) S = Sub-area

The equipment have been classified in different types, by means of assigning a corresponding letter to the kind of equipment:

This equipment classification can be defined by every company and according to its needs. It is important to avoid changing them frequently, because it may affect the maintenance control. The coding goal is to make it easier to identify the active by the responsible workers in the operation's area, as well to improve the quality in the Planned Maintenance.

General example to identify the active

If we talk about the technical location of Process I and in the sub-area I, different operation equipment are installed:

- Shredding machine 1,

- Shredding machine 2,

- Shredding machine 3,

- Dough Mill, etc.

Step No. 1 We stablished the technical location of all the processes and the sub-areas.

Step No.2 Elaborating an active coding, as the next one:

- Technical location:

- Equipment: Shredding Machine 1.

Remembering the nomenclature: The first character start with a letter and indicates the sub-area coding; the second and third letter correspond to the type of equipment that has been previously classified and at the end a consecutive number.

Data required for the equipment coding:

- Sub-area location belonging to the active

E= Sub-area I (It indicates the name of the sub-area belonging to the process)

- Name of the equipment to register: (See the equipment classification by letter)

D= Shredding machines

Consecutive number to identify the active: 01

The equipment coding would look like this:

- ED01 = Shredding machine No.1

- ED02 = Shredding machine No.2

- ED03 = Shredding machine No.3

- EM01 = Dough Mill

If you read this very fast, you will understand that the equipment with the ED01 code is located in the sub-area I, its referring to a shredding machine and it has an exclusive numbering. These will give confidence to the teamwork and promote organization and effectiveness in their duties. We will achieve this way a record of all the maintenance as well as the costs per service and repairs.

Structurally:

- 1st Level XX Name of the Plant

- 2nd Level XX-01- Process I

- 3rd Level XX-01-01-Sub-area I

Registered equipment in the sub-area:

- ED01 = Shredding machine No.1

- ED02 = Shredding machine No.2

- ED03 = Shredding machine No.3

- EM01 = Dough Mill

If you want to know more about what is done in the next stages, I invite you to read my next blog:

Continuous Improvement at Casa Sauza

Feel free to contact us and schedule your guided tour visit to our facilities, you will have an amazing time!

.png?width=50&height=50&name=10.CS-Redondo%20(1).png)