The Autonomous Maintenance is part of the TPM, that means Total Productive Maintenance. Discover how is it implemented and all the benefits it provides.

How is the Autonomous Maintenance performed in Casa Sauza?

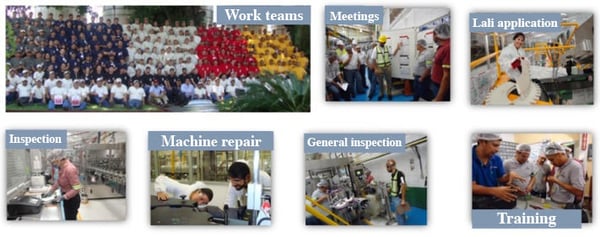

It is an activity that is implemented in the equipment where the whole personnel is involved in order for everyone to develop an interest and committment with their tools and machines. This process is done through a deep cleaning and inspection of their equipment, learning how to do it from several training, bringing as a result a higher education in all the operators, turning them into more sensitive individuals and making them more aware of faults or abnormalities in the equipment. By doing so, we make sure all the pieces of equipment are working in the best possible way and in optime conditions.

What are the Benefits of the Autonomous Maintenance?

Performing the autonomous maintenance supports us to keep the service life of the equipment, avoiding damage and wear as well as reducing accidents and increasing the production in all the processes.

How many steps are there in the Autonomous Maintenance Pillar?

There are 7 steps building this pillar:

- Step 0 : Security.

- Step 1: Initial cleaning

- Step 2: Elimination of pollution sources and difficult access areas

- Step 3: Realization of provisional cleaning, inspection, and greasing standards

- Step 4: Improving the operator's technical skills

- Step 5: Autonomous Inspection to the Equipment

- Step 6: Procedures, standards, and work rules

- Step 7: Autonomous Equipment Management

What is the Step 0 Approach?: Eliminate accidents

Avoid accidents through the application of:

- Blocking all kinds of energy existing in the equipment before performing tasks such as equipment intervention whether for cleaning, modifications, or tests.

- Symbology colocation in each procedure and verification.

- Checking all the areas and accessories to avoid any kind of accidental move.

- Identifying the equipment risks, machinery or installation, in which the operators may get involved such as: moving parts, blades, chemical substances, temperature, etc.

Initial Cleaning: What is the Step 1 approach?

Turning ourselves into human sensors to find and solve abnormalities and stabilize the equipment operation through cleaning and inspection. Using our senses to visualize and detect any obvious abnormality. This is done by touching and observing the components and parts while cleaning, focusing on 7 types of abnormalities:

- Conditions or insecure places

- Minor defects

- Basic conditions without being met

- Inaccessible places

- Contamination sources

- Quality defects sources

- Unnecessary parts

Thorough cleaning and inspection, we are able to prevent loose screws or pieces, breaks, wears, desalination, poorly done solders and cables, oxidation, oil fugues, unnecessary parts, broken bands, etc.

In the next publications we will continue talking about the next steps:

Autonomous Maintenance in the Administrative Process

Feel free to contact us and schedule your guided tour to Casa Sauza, where you will experience an amazing trip to our agave fields, plant facilities and learn about the tequila making process and our methodology.

.png?width=50&height=50&name=10.CS-Redondo%20(1).png)

.jpg?width=600&name=unnamed%20(1).jpg)