The SMED (Single-Minute Exchange of Die) is a valuable tool that can help us to make our lives easier. We can apply this in any kind of activity, whether at work or at home. In this article, we will tell you about how we have implemented SMED in Casa Sauza to reduce the re-change time.

What is SMED?

SMED is a methodology that is applied in business contexts to reduce the tool and format change time, the goal is to reduce it to less than 10 minutes and turn it into just one digit (9).

The SMED methodology is divided in 7 steps, and they consist in the following:

- Step 1- Identify the change, tool and format activities and list them down including their processes.

- Step 2- Identify the internal and external activities and make a list where the two classifications are clear.

- Step 3- Turn the internal change into external.

- Step 4- Improve the internal changes and identify which internal activities can be improved.

- Step 5- Eliminate adjust activities and eliminate all the unnecessary ones that may interfere with the equipment process, in other words: keep it simple.

- Step 6- Improve the external activities.

- Step 7- Standardization and training.

What is the Change Time?

It is the time that goes by starting with the last piece of the first product, until the first piece of the next product comes out.

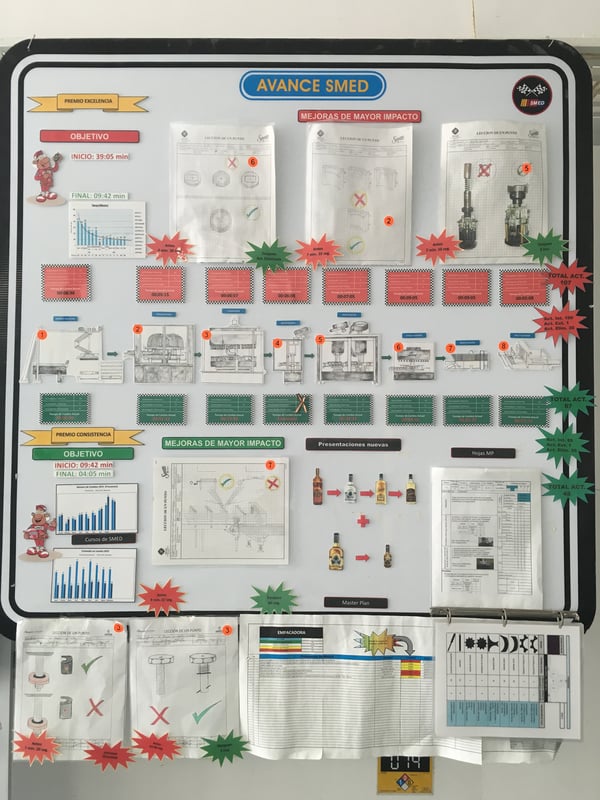

Implementing SMED in the Casa Sauza Bottling

Thanks to the developed SMED methodology, we have implemented a new way of bottling in Casa Sauza, and we have obtained excellent benefits due to the fact that we don't have warehouses to store the final product, so all of our beverages have to be delivered just in time. This means that we are exposed to make changes to the presentations, formats or tools very frequently.

SMED is very important in Casa Sauza because we are implementing this program in all our work areas day by day.

Our first SMED in bottling in Casa Sauza

Some time ago, the team working in Casa Sauza performed a format and tool change in approximately 30 minutes. These represented wasted time and money.

With the implementation of SMED, we obtained our first achievement in a format change of a circled bottle to a square bottle of 100 years 750 ml. a steel-cap 750 ml. We were able to reduce the time from 30 minutes to 9 minutes 42 seconds. This was our first SMED registered in Casa Sauza.

This achievement was performed thanks to the brainstorm we obtained from the operators that are located in the bottling lines, because they are the ones that know the equipment perfectly well and have a better idea on what to implement to reduce the tool and format time.

Once we obtained our first achievement, we started our race looking for an improvement and to replicate the brainstorms that were proposed on our first exchange that led us to the first SMED. We were more and more motivated to move forward and achieve better results for all the other presentations in less than 10 minutes.

This is how the SMED methodology has taken us to be one of the best companies in the tequila industry regarding formats and tool change.

Would you like to know more about the SMED benefits?

If you want to know and learn more about the high impact improvement that helped us to achieve our first SMED, learn more about the focused improvement in the following blogs:

Continuous Improvement at Casa Sauza

The Best Focused-Improvement Tool at Casa Sauza

.png?width=50&height=50&name=10.CS-Redondo%20(1).png)