Quality is very important to Sauza which is why automatic inspection systems play a key role in the elaboration of our products. Thanks to them, we can guarantee customer satisfaction by offering products that meet the quality specifications that we have set for them.

The automatic inspection systems that we currently have can be divided into 2 groups:

Automatic Inspection Systems

Those that have control on the product

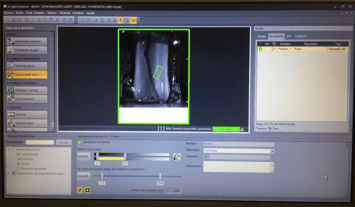

These systems, when detecting that the specification is not met, take an action to correct the product. For example, in our case, we have the one that regulates the bottle's orientation. This system inspects the bottles and if it detects any that are not correctly oriented, it gets rotated by means of servo motors before being labeled.

Those that separate the product from the rest

These systems, not being able to correct the product, have two other options:

- Separate those products that don't meet our standards from the rest

- Stop the machine that generated the failure so that the product can be separated manually and avoid further defects

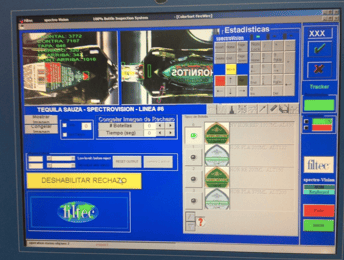

For example, we have an equipment that detects if a bottle is missing a labels. In case a label is missing, the bottle is separated from the production line. Another example is the equipment that makes sure that the boxes carry all the bottles filled with liquid, in case of not fulfilling this condition, it separates them from the production line.

Why Do We Take Such Care For the Quality of Our Products?

Because we are aware of the impact that quality has on our finished products. There are 3 main impacts that motivate us to invest resources on our automatic inspection systems.

This impact is presented here from the least serious to the most serious ones:

1. Impact on Re-Processes

This is the least significant one since by re-processing we mean those defects that are detected during the production process. They have an impact on the production cost, since each re-processing involves recovering a product that had already gone through a certain process. When a product doesn't meet our specifications, we recover the reusable materials of the product and discard those that cannot be reused. The product then undergoes the whole process that generated the defect once again.

2. Impact on Brand Trust

The trust that our clients put on us is a mayor issue for Sauza. If our clients stop trusting our brand, we'll loose them.

3. Legal Impact

If we don't cover meet the legal requirements of the several norms, laws, and ISO's in which we are certified, we can be fined for it or even lose our certifications, in addition to also affecting customer satisfaction.

ISO's

ISOs are really important to us since they have a direct impact on the trust that customers put in our products. ISO's validate the procedures and documentation of our products. The ISO´s in which we are certified are:

- ISO 9001

- ISO 14001

- ISO 22000

- OHSAS 18001

BASC

We also have the BASC -Business Alliance for Secure Commerce- certification, which is an international business alliance that promotes secure trade in cooperation with governments and international organizations. This certificate helps build trust in the businessmen that we work with.

So now you know, for Sauza, there's nothing that matters most than delivering the product that our clients enjoy so much, with the quality that has always defined us. We work to keep our quality standards so that you can be sure that you are buying a reliable, safe and of unbeatable quality tequila.

If you want to learn more about our production processes, do come and visit Casa Sauza. Take one of our guided tours and learn all about the production of tequila, on-site.

.png?width=50&height=50&name=10.CS-Redondo%20(1).png)